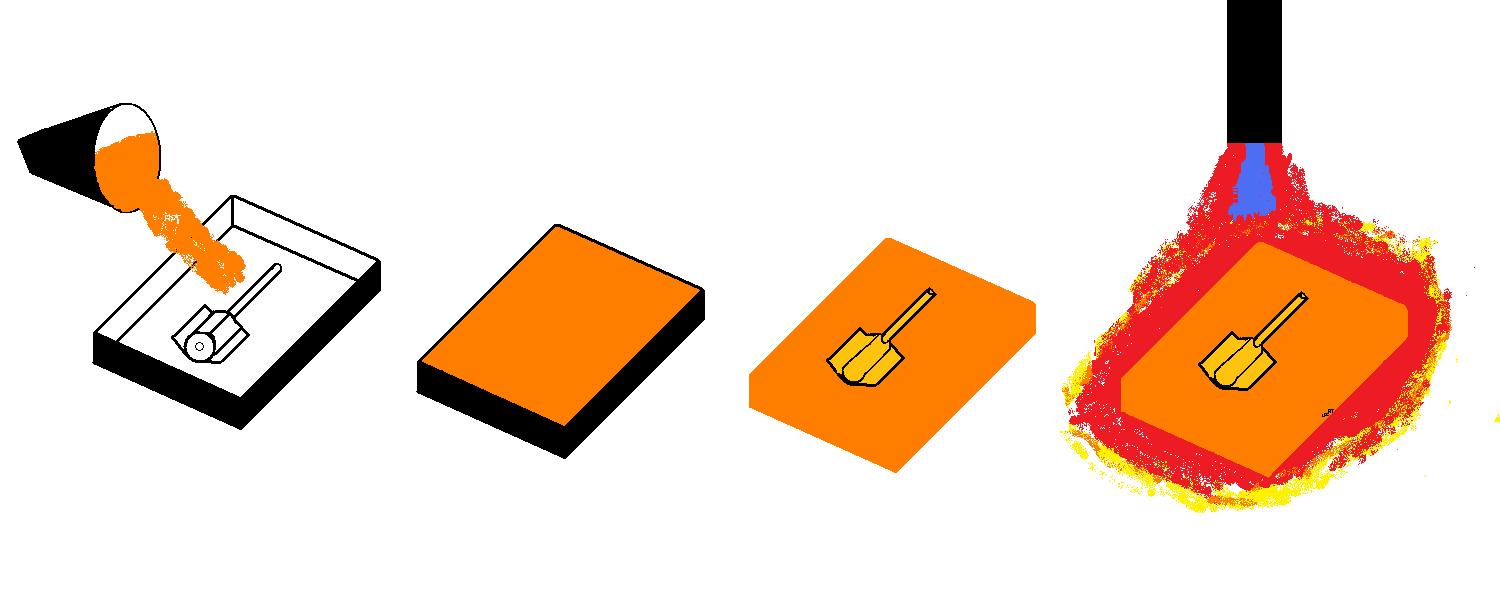

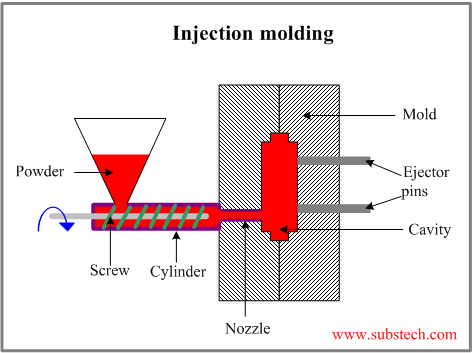

Ceramic injection molding cim is a net shaping process which enables large scale production of complex shaped components for use in a diverse range of industries.

Definition of molding in ceramics.

It is a combination of plaster mold casting and investment casting.

Pottery of this cast was found throughout the region stamp mould cast.

These casting processes are commonly used to make tooling especially drop forging dies but also.

How to use sculpture in a sentence.

It combines plastic injection molding techniques and performance attributes of ceramic and metal powders.

The shaw process and the unicast process.

Press mold definition is a cast iron mold used in glassmaking.

In pottery press molding refers to the process in which clay is forced into a mold in order to take on a certain shape.

Sculpture definition is the action or art of processing as by carving modeling or welding plastic or hard materials into works of art.

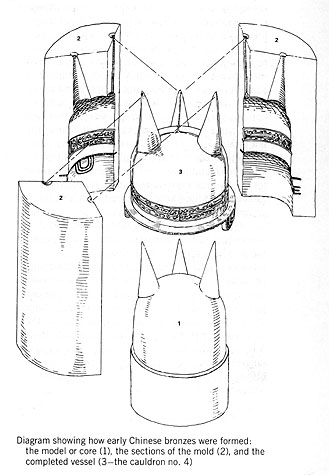

Ceramic mold casting also known ambiguously as ceramic molding is a group of metal casting processes that use ceramics as the mold material.

A hollow form or matrix for shaping a fluid or plastic substance.

A frame or model around or on which something is formed or shaped.

Molding definition the act or process of molding.

Ceramic injection molding cim uses ceramic powders such as alumina.

There are two types of ceramic mold casting.

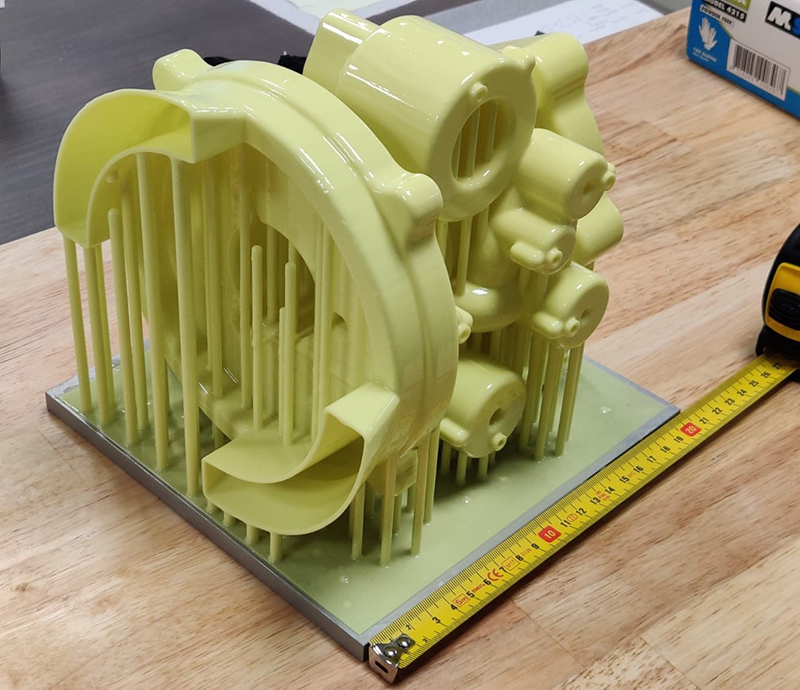

The ceramic molding process is a production method which guarantees the precision required and also gives a good surface finish using a high temperature method to better structure and shape parts.

Ceramic injection molding is ideal for high volume production of complex tight tolerance components.

The pressing of soft clay into or onto a mold for shaping.

The process of bringing a kiln to maturity.

A glassy or matt decorative and or waterproof surface applied and fired to ceramic forms.

This process also gives a low grade of toleration.